- comelyweb@gmail.com

- Printing Information

- October 3, 2025

- No Comments

What Printing Process is Used for Newspapers?

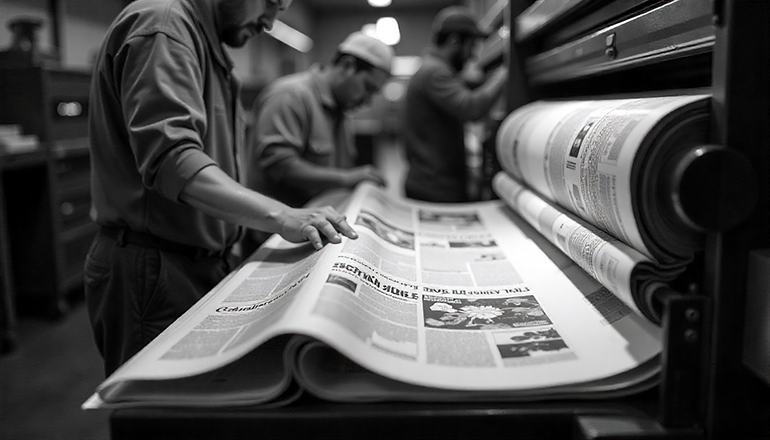

Ever wondered how your morning paper lands on your doorstep, crisp and full of the latest news, day after day? It’s a marvel of modern engineering, really. The printing process used for newspapers has evolved over centuries, but today, it boils down to efficiency, speed, and quality that can handle massive runs without breaking a sweat. If you’re curious about what printing process is used for newspapers, you’re in the right spot. We’ll dive deep into the nuts and bolts, starting with the dominant method: offset lithography. This isn’t some fancy tech jargon—it’s the workhorse behind billions of printed pages worldwide.

Picture this: In bustling print houses, giant rolls of newsprint zoom through machines at breakneck speeds, getting inked with stories from around the globe. The newspaper printing process isn’t just about slapping ink on paper; it’s a symphony of plates, rollers, and precise timing. Offset printing shines here because it delivers sharp text, vibrant images (when needed), and does it all cost-effectively for high volumes. But why offset over others? Well, alternatives like gravure or digital have their places, but for the daily grind of newspaper production, offset rules the roost.

Let’s back up a bit. Newspapers demand quick turnaround—think deadlines tighter than a drum. The printing process for newspapers must crank out thousands, sometimes millions, of copies overnight. Offset lithography, especially the web offset variety, fits the bill perfectly. It uses aluminum plates etched with the page layouts, transferring ink via a rubber blanket to the paper. This indirect method prevents wear and tear, ensuring consistent quality even after hours of running.

But hey, the world of printing isn’t static. With digital tech creeping in, some smaller runs or customized editions lean toward inkjet or laser methods. Still, for the big leagues like major dailies, offset remains king. Research shows that most newspapers stick with this tried-and-true approach because it’s reliable and economical. According to industry insights, offset handles the porous nature of newsprint like a champ, absorbing ink without smudging.

If you’ve ever flipped through a broadsheet and marveled at the fold, that’s post-press magic, but it all starts with the print. In this article, we’ll unpack everything from the history to the how-to, pros and cons, and even peek at what’s next. Whether you’re a printing enthusiast, a journalism buff, or just someone killing time with a coffee, stick around. By the end, you’ll know exactly what printing process is used for newspapers and why it matters in our digital age. Let’s roll up our sleeves and get into it.

Key Points:

- Offset lithography is the primary printing process used for newspapers, offering speed and cost savings for large-scale production.

- It seems likely that digital printing will gain ground for niche markets, but offset dominates due to its efficiency.

- Research suggests that environmental tweaks, like soy-based inks, are making the newspaper printing process more sustainable.

- While controversies around print’s decline exist, evidence leans toward hybrid models blending print and digital for future viability.

Table of Contents

ToggleWhy Offset Printing Dominates Newspaper Production

Offset printing isn’t just popular; it’s practically synonymous with the printing process for newspapers. This method, also known as offset lithography, relies on the principle that oil and water don’t mix. Ink sticks to image areas on a plate, while water repels it from non-image spots. For newspapers, this translates to fast, high-quality output on cheap newsprint.

In practice, web offset presses—think massive machines fed by continuous paper rolls—handle the heavy lifting. These beasts can print up to 80,000 copies per hour, making them ideal for dailies like The New York Times. The process starts with computer-to-plate (CTP) technology, where digital files laser-etch plates directly, skipping old-school film steps. It’s quick, reduces errors, and keeps costs down.

One big plus? Versatility. Offset can do spot colors or full CMYK for those eye-catching front pages. Plus, it’s forgiving on absorbent paper, avoiding the bleeds you might see in other methods. If you’re wondering what printing process is used for newspapers in most plants, offset’s your answer—it’s been the standard since the mid-20th century.

Step-by-Step: How the Newspaper Printing Process Works

Curious about the nitty-gritty? The newspaper printing process unfolds in stages, each optimized for speed. First, pre-press: Editors layout pages using software like InDesign, then RIP (Raster Image Processor) converts them to plate-ready files.

Next, platemaking. Lasers etch aluminum plates—one per color per page. These mount on cylinders in the press. As the web of paper flies through, plates transfer ink to a blanket cylinder, which presses it onto the paper. For color, multiple units align CMYK layers perfectly.

Post-print, the magic continues: Folding, cutting, and bundling happen inline. Modern presses even insert ads dynamically. It’s a far cry from Gutenberg’s day, but the goal’s the same—deliver news hot off the press.

Have you ever stopped to think about the journey a simple newspaper takes from digital file to your hands? The printing process used for newspapers is a fascinating blend of old-school craftsmanship and cutting-edge tech, honed over centuries to meet the demands of mass communication. In this deep dive, we’ll explore every angle, from historical roots to modern innovations, ensuring you get a complete picture. We’ll cover the dominant methods, their mechanics, benefits, alternatives, and even the environmental impact. Along the way, I’ll weave in details from reliable sources like Wikipedia’s production overview and printing industry sites, all paraphrased in my own words for freshness.

Let’s start by expanding on the basics. The core newspaper printing process revolves around offset lithography, but it’s not one-size-fits-all. For high-circulation papers, web offset—either coldset (air-dried ink) or heatset (oven-dried for gloss)—is the go-to. Coldset suits black-and-white dailies on uncoated newsprint, while heatset handles magazines with better color pop. Gravure, with its engraved cylinders, pops up for ultra-high volumes, like national inserts, because it excels at consistent long runs. Flexography, using flexible plates, occasionally tags in for packaging or specialty sections, but it’s less common. Digital printing, via inkjet or toner, is rising for short runs or personalized editions, like local weeklies.

Diving deeper into history, the history of newspaper printing processes traces back to the 15th century with Johannes Gutenberg’s movable type press, which revolutionized information spread. By the 1600s, weekly papers emerged in Germany, printed on hand-operated wooden presses. The 19th century brought steam-powered rotary presses, like those from Koenig & Bauer, boosting speeds dramatically—The Times of London printed 1,100 sheets per hour in 1814. Iron presses followed around 1800, attributed to Earl Stanhope, making production sturdier. Fast-forward to the 20th century: Offset lithography took over in the 1950s, replacing letterpress for its efficiency. Hot type (molten lead) gave way to cold type (phototypesetting) in the 1970s, and by the 1990s, computer-to-plate streamlined everything. Today, digital workflows dominate, but the essence remains: Fast, reliable mass printing.

Why does offset lithography stand out in the advantages of offset printing for newspapers? For starters, it’s incredibly cost-effective for large volumes. Once plates are set, per-unit costs plummet—perfect for runs over 1,000 copies. Quality is another win: Sharp text, accurate colors, and consistent results, even on porous newsprint. Speed? Presses churn out pages at 100,000 copies per hour, meeting tight deadlines. It’s versatile too, handling various paper types and finishes. Compared to digital, offset saves on ink for big jobs, and unlike gravure, setup is cheaper for mid-to-large runs. Drawbacks? Initial plate costs make it less ideal for tiny batches, but for newspapers, that’s rarely an issue. Industry pros note offset’s reliability in high-humidity environments, reducing smudges.

Now, let’s break down other printing processes used in newspapers. Gravure printing engraves images into cylinders, filling grooves with ink for transfer. It’s ace for high-volume work, like magazines or packaging, offering rich colors and fine details. Pros: Long-lasting cylinders for millions of impressions, minimal waste. Cons: Pricey setup, so it’s for mega-runs only. In newspapers, it’s used for supplements or catalogs. Flexography uses rubber plates for quick-drying inks, great on uneven surfaces. It’s eco-friendly with water-based inks but lags in fine detail compared to offset. Digital printing skips plates altogether, jetting ink directly or using toner. Ideal for under 500 copies, it allows variable data—like personalized headlines. Pros: Fast setup, no waste from makeready. Cons: Higher per-unit costs for volume, potential quality dips on newsprint.

Turning to modern newspaper printing technologies, the landscape is shifting. Computer-to-plate (CTP) eliminates film, using lasers for direct etching—faster, greener. High-speed inkjet presses, like those from Koenig & Bauer, blend digital flexibility with offset speeds, hybridizing for variable content. AI optimizes ink usage and predicts maintenance, cutting downtime. Sustainability drives innovations: Soy or vegetable inks replace petroleum-based ones, and recycled newsprint is standard. Trends include waterless offset, ditching dampening solutions for less waste. For small publishers, cloud-based workflows enable remote proofing. As print volumes dip with digital news, these techs keep physical papers viable.

To visualize, here’s a comparison table of key processes:

| Process | Description | Pros | Cons | Best for Newspapers When… |

|---|---|---|---|---|

| Offset Lithography | Ink transfers from plate to blanket to paper | Cost-effective for large runs, high quality, speed | High setup costs for small runs | Daily high-circulation papers |

| Gravure | Engraved cylinders hold ink | Excellent for long runs, consistent quality | Expensive cylinders, long prep | National inserts or magazines |

| Flexography | Flexible plates with quick-dry ink | Versatile substrates, eco-friendly | Lower detail for text-heavy | Packaging or specialty sections |

| Digital | Direct inkjet or toner application | Quick setup, variable data | Higher cost per unit for volume | Short runs or customized editions |

Expanding on the step-by-step newspaper printing process, it all kicks off with content gathering—reporters file stories, editors polish. Pre-press: Layout in software, color correction, proofing. Then, RIP converts to bitmap for plates. Printing: Reels unwind at 50 mph, inked via towers (four for color, per side). Configurations like blanket-to-blanket print both sides at once. Post-press: Slitting, folding into signatures, bundling for distribution. Quality checks happen inline with sensors spotting defects. The whole shebang adheres to standards like ISO 12647 for color accuracy.

Environmental considerations can’t be ignored in the printing process for newspapers. Newsprint comes from sustainable forests, with recycling rates over 70% in many regions. Inks have gone green—soy-based reduce VOCs. Waterless printing cuts chemical use. Yet, energy-hungry presses pose challenges; some plants offset with solar. The industry pushes for circular economies, reusing plates and minimizing waste. It’s not perfect, but strides are evident.

Peeking ahead, future trends in newspaper printing processes point to hybridization. Inkjet-overlay on offset for personalization. 3D printing? Maybe for prototypes. AI-driven predictive analytics will slash errors. As digital media grows, print might niche into premium, tactile experiences. Sustainability will dominate, with bio-inks and zero-waste goals. Expect more automation, like robotic plate loading.

Now, for some searchable FAQs on what printing process is used for newspapers:

- What is the most common printing process for daily newspapers? Offset lithography, specifically web offset, handles the volume and speed needed for dailies.

- How does offset printing differ from digital for newspapers? Offset uses plates for mass runs, cheaper per unit; digital skips plates for quick, small batches but costs more at scale.

- Why is gravure printing sometimes used in newspaper production? For its durability in ultra-high volumes, like inserts, offering consistent quality over millions of copies.

- What role does technology play in modern newspaper printing? CTP and AI streamline processes, reducing waste and boosting efficiency.

- Is the newspaper printing process environmentally friendly? Improving with recycled paper and green inks, but energy use remains a hurdle.

- How has the history of newspaper printing evolved? From Gutenberg’s press to steam rotaries, then offset in the 20th century, now digital hybrids.

In conclusion, the printing process used for newspapers—led by offset lithography—remains a cornerstone of information delivery, blending tradition with innovation. As tech advances, it adapts, ensuring papers stay relevant. Whether you’re in the industry or just a reader, appreciating this process adds depth to every page turned.